In Formula 1 you win or lose because of the tyres. They decide. They are the cars' only contact point with the track, their hands, their feet. If they are warm or cold, fit or fatigued, slow or fast, soft or hard, inflated or flat, you arrive earlier or later. It is said that a man's elegance can be judged by his shoes, the first thing to look at to evaluate him. For Formula 1 cars it's the same thing. Even if the dress is very elegant, without good shoes you can't win.

And if shoes break you can even die. Tires have accompanied the entire history of Formula 1, have determined it, seasoned it and they have changed with it. Silent but decisive protagonists.

Formula One tyres are a high performance racing tyre designed specifically for use by Formula One cars. The tyres have undergone significant changes throughout the history of Formula One, with different manufacturers and specifications used in the sport. A Formula One tyre is often designed to last for, at most, 200 kilometres and - like everything else on a F1 car is constructed to be as light and strong as possible. Even so, F1 tyres are far tougher than those on used on ordinary road cars, which may be able to last for 20,000 miles or more, but would not stand a chance against the rigours of F1 racing. Often different type of tyre compounds will be avaible to teams, such as hard and soft or special tyres for use in wet conditions.

Giovanna Amati.

Over the years Formula One tyres have evolved and changed many times. The first tyres used in Formula One during the 1950's were tall and thin and featured tread. Generally both the front and rear tyres were the same size. By the early 1960's tyres had become wider and flatter. In the mid 60's rear tyres started to become larger than the front tyres.

Slick racing tyres were first introduced during the 1971 Formula One season by Goodyear. This increased the size of the contact patch between tyre and track providing more grip than the treaded tyres used previously. During the 1970's the size difference between rear and front tyres increase with rear tyres becoming wider and front tyres smaller. In 1977 Michelin introduced the first radial tyre. This would eventualy become the normal tyre due to their construction giving them a more constant ride height which was important due to the ever increasing reliance of aerodynamics.

By the 1980's there were several different companies providing tyres which would lead to fierce competition to make the best tyre. Due to this special tyres for use in qualifying began to appear. These tyres would give lots more grip but would only last for a short amount of time. During the 80's and early 1990's tyre shapes and sizes began to equal out again with both rear and front being similar sizes. In 1985 tyre blankets were used for the first time. These are blankets that are used to warm tyres up while they are in the pits and when the car is on the grid. Without this prior heating the tyres would take on average two laps before they got to their prime working temperature.

In 1998 grooved tyres were introduced with 3 grooves in the front tyres and 4 grooves in the rear tyres. Between 1999 and 2008, regulations required the tyres to feature a minimum of four grooves in them, with the intention of slowing the cars down (a slick tyre, with no indentations, is best in dry conditions due to the larger contact patch). They could be no wider than 355 mm and 380 mm at the front and rear respectively and the maximum diameter was 660 mm (670 mm for wet tyre).

In 2005, tyre changes were disallowed in Formula One, therefore the compounds were harder as the tyres had to last the full race distance (around 300 km).

Tyre changes were re-instated in 2006, following the dramatic and highly political 2005 United States Grand Prix.

Slick tyres were reintroduced at the beginning of the 2009 season along with aerodynamics changes intended to shift the balance towards mechanical grip in an attempt to increase overtaking.

The purpose of the tyre determines the compound of the rubber to be used. In extremely wet weather, such as that seen in the 2007 European Grand Prix, the F1 cars are unable to keep up with the safety car in deep standing water due to the risk of aquaplaning. In very wet races, such as the 2011 Canadian Grand Prix, the tyres are unable to provide a safe race due to the amount of water and so the race can be red flagged. The race is either then stopped permanently, or suspended for any period of time until the cars can race safely again.

Goodyear. PIN IT.

During the 1950s and 1960s, Formula One tyres were supplied by Dunlop, Firestone, Continental and Goodyear. In 1958, Dunlop introduced its R5 racing tyre, replacing the cotton fabric of the earlier R1 to R4 tyres with nylon fabric, allowing for a reported 12 lb reduction in tyre weight. During the 1960s, Dunlop introduced improved nylon casings, reduced aspect ratio, significantly increased tyre width, and the use of synthetic rubber.

Slick tyres were introduced to Formula One by Firestone at the 1971 Spanish Grand Prix. 1975's Ferrari 312T utilised a Goodyear 26.0"x16.2"-13" slick tyre (overall diameter x width) in the rear on a 13"x18" rim, with a Goodyear 20.0"x9.2"-13" slick tyre in the front on a 13x10" rim.

For the 1981 season the maximum diameter of the rear tyre was reduced to 26.0", while the diameter of the front tyres was increased. Therefore from 1981 until 1992, Goodyear supplied white sidewall marked Eagle tyres with the sizes of 25.0"x10.0"-13" in the front and 26.0"x15.0"-13" in the rear. For the 1993 season, the complete wheel width of the rear was reduced from 18" to 15", prompting Goodyear to change to yellow sidewall markings to correspond to the new, narrower rear tyres which were approximately 12.8" wide, down from the previous 15.0".

Tess Brelia, the only lady tyre-changer in the Indycar series in Surfers' Paradis in 2003.

For the 1997 F1 season, Bridgestone joined Goodyear in supplying tyres to F1 competitors, creating a competition between the two manufacturers.

For 2007, Bridgestone became the sole tyre supplier in Formula One with the withdrawal of Michelin and introduced four compounds of tyre, two of which are made available at each race.

Models pose on bridgestone tyres during a photocall at the race track.

The harder tyre (referred to as the "prime" tyre) is more durable but gives less grip, and the softer tyre (referred to as the "option" tyre) gives more grip but is less durable. Both compounds have to be used by each car during a race and the softer tyre had a painted white stripe in the second groove to distinguish between compounds.

Michael Schumacher changing a tyre of his Ferrari F1.

Michael Schumacher's Ferrari F1.

Michael Schumacher checks a tyre of his Ferrari F1.

Michael Schumacher checks a tyre of his Ferrari F1.

This was introduced after the first race of the season when confusion occurred because a small dot was put on the sidewall of the tyre, instead of the white stripe. Upon the reintroduction of slicks in 2009, the sidewalls of the softer tyres were painted green to indicate the difference in compound, as there were no longer any grooves in tyres. Each team must use each specification during the race, unless wet or intermediate tyres are used during the race, in which case this rule no longer applies.

On 2 November 2009, Bridgestone announced their withdrawal from Formula One at the end of the 2010 season. Michelin, Cooper Avon and Pirelli showed interest in taking over the role of tyre supplier. In June 2010, it was announced that Pirelli would be the sole tyre supplier for 2011 and would receive a three-year contract after spending three years as an official tyre supplier for both Grand-Am Rolex Sports Car Series and FIA World Rally Championship auto racing tournaments (Grand-Am Rolex Sports Car Series switched to Continental Tires and FIA World Rally Championship switch to Michelin respectively in 2011). During August 2010, Pirelli commenced its test programme with the Toyota TF109 at the Mugello Circuit with Nick Heidfeld as the test driver. From 2011, the feeder GP2 Series used identical Pirelli tyres as in F1.

In 2009 with the removal of the 4 14 mm (0.55 in) grooves the front tyres gained proportionally larger contact patch. In 2010 the front tyres were narrowed from 270 mm (11 in) to 245 mm (9.6 in), in order to improve the balance of grip between the front and rear. In 2011, with the sole tyre supplier having been changed from Bridgestone to Pirelli, the rules were the same as the 2010 season rules concerning the tyres. All teams still were required to use each type of dry tyre compound supplied in the race, and drivers that made it through to Q3 still had to use the same tyres they used to set their fastest qualifying time with to start the race. However, the way of denoting different tyre specifications was changed. Rather than a green stripe denoting a softer compound, for each tyre specification, the lettering on the tyre would have a specific colour. The hard compound would have silver lettering, the medium compound would have white lettering, the soft tyres would have yellow lettering and the super-soft tyres would have red lettering. For the wet tyres, the intermediate tyres would have light blue lettering and the full wet tyres would have orange lettering.

Pirelli tyre test Abu Dhabi 2011.09.

At the 2011 Malaysian Grand Prix, Pirelli introduced a coloured band around the outside of the tyre on the softer of the two dry compounds. This was due to confusion during the first round of the season. This measure was said to be a stop gap, with a permanent solution due to be implemented at the first European race of the season. The coloured line featured at the Chinese Grand Prix too. From the Turkish Grand Prix, the permanent solution was implemented; the option compound had a new marking. The option tyre had two thick coloured lines between the Pirelli and P Zero logos of each tyre, which made it easier to see the colour of the marking when the tyre rotates. The prime tyre remained the same markings as previously, though later in the season had the sidewall updated with the new markings.

Sochi, Russia. 27th April 2016. Mercedes mechanic.

In 2016 new tyre rules were introduced. Pirelli will nominate 3 different compounds of slick tyres to bring to each race. Each team will have 13 sets of dry tyres for the race weekend. Of the 13 sets, two sets of tyres are chosen by Pirelli to be reserved for the race. Additionally, one set of the softest compound will be set aside for Q3. Teams are free to choose what they like for their ten remaining sets from the three chosen compounds. Each driver must use at least two different dry weather compounds during the race (including one set of the mandatory race tyres), and drivers who make it to Q3 must start the race with the tyres they set their fastest Q2 lap on. Teams must inform the FIA eight weeks before the start of a European event and 14 weeks before a non-European race their tyre choices.

For the 2017 F1 season, significantly wider Pirelli tyres were introduced at both the front and rear axles, while the overall diameter of the tyres was increased by 10mm. Front tyre size increased to 305/670-R13 up from the previous 245/660-R13, while rear-tyre size increased to 405/670-R13 up from the previous 325/660-R13. In 2017 and 2018, the FIA Formula 2 Championship continued to use the pre-2017 size Pirelli F1 tyres.

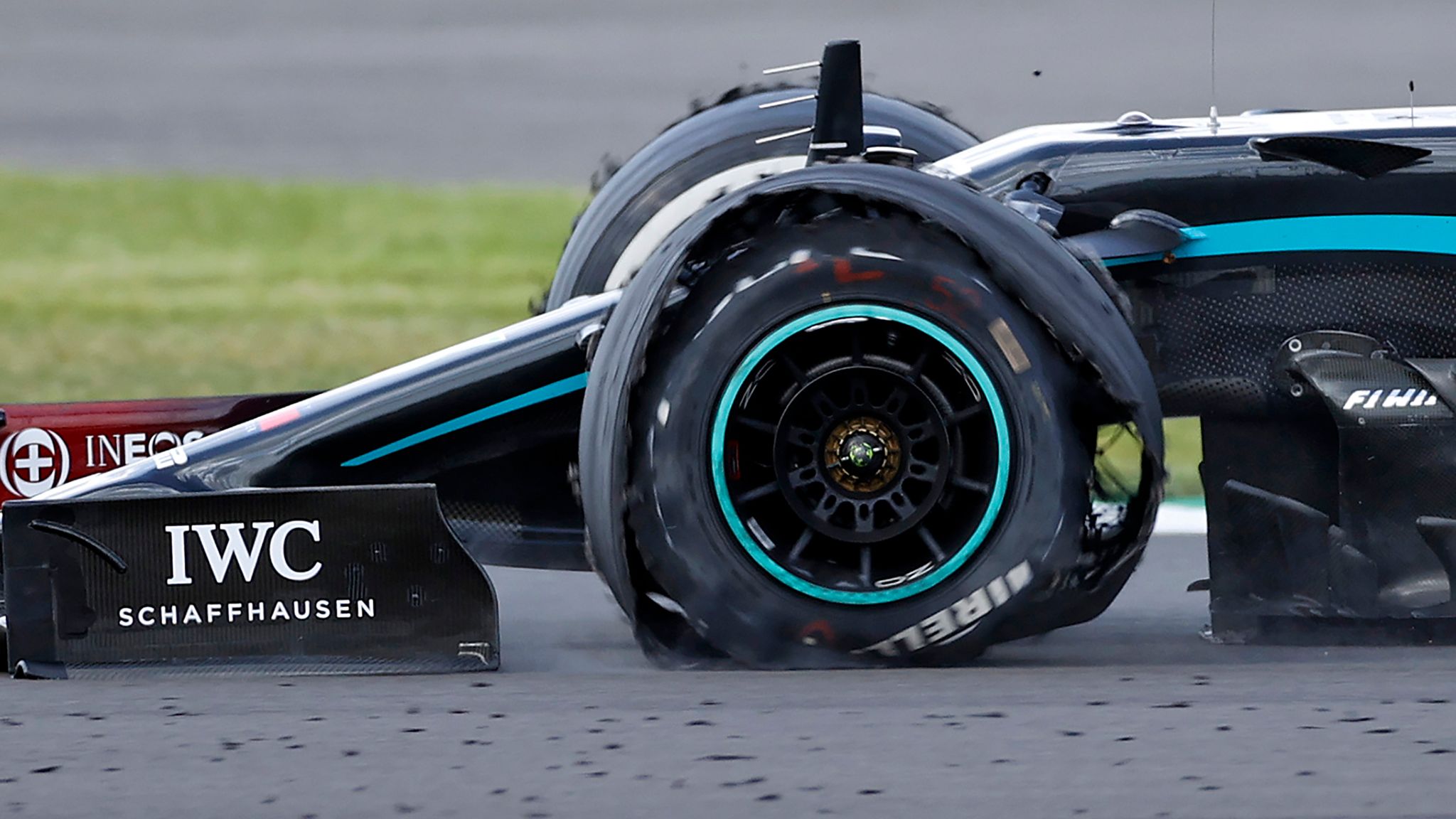

A damaged tyre in 2018.

Pirelli introduced two new tyre compounds for the 2018 F1 season, Hypersoft (pink) and Superhard (orange). The Hard tyre became ice blue.

Pirelli tyres 2019.

Heading into the 2019 season Pirelli reduced the tyre range from seven to five dry weather compounds, they also scrapped the tyre naming system such that the tyres will denoted at each grand prix independently as hard, medium and soft with white, yellow and red sidewalls respectively rather than having a separate name and colour for each of the five tyres. The change was implemented so that casual fans could better understand the tyre system.

Make Cars Green campaign.

Bridgestone used tyres with green grooves for the 2008 Japanese Grand Prix. The tyres had the grooves painted green, as part of a promotion by the FIA to reduce the impact of motoring on the environment, called Make Cars Green. The softer of the two types of tyre still had the second innermost groove painted white, as per normal. Rubens Barrichello (top) demonstrates the "prime" compound, whilst Nick Heidfeld is running on the "option" compound, distinguished by the fact that one of the grooves is white.

Upon the return of slicks at the beginning of the 2009 season the white stripe to indicate differences between the tyres was no longer possible due to the lack of grooves on the tyres. Subsequently, in a continuation of the Make Cars Green tyres in Japan, Bridgestone painted the sidewalls of the option tyre green instead.

Rain tyres (full wets) as seen on Lewis Hamilton's car during the 2016 Monaco Grand Prix.

There are seven tyre compounds available for the 2020 season. Two of these are for wet weather driving, the intermediate (indicated by a green sidewall) for light standing water conditions, and the full wet (indicated by a blue sidewall) for heavy standing water. These will be available to all the teams at every Grand Prix. The remaining five tyre compounds are for dry running and are denoted C1 to C5, with C1 being the hardest tyre, meaning it provides the least grip but is the most durable, and C5 being the softest, having the most grip but being the least durable. The five tyre compounds form a sliding scale of durability and grip levels.

F1 Pirelli tyre range.

Pirelli will nominate three of the compounds to be run at each race. Of these three, the hardest compound will be named the hard tyre for that weekend and will be denoted by a white sidewall, while the softest compound will be named the soft and will be denoted by a red sidewall, with the third of the nominated tyres named the medium tyre which will be denoted by a yellow side wall. Drivers have to use at least two of the dry weather compound tyres during a race, unless the race is affected by wet weather.

British GP. Sky sports.

The exception to this is at testing, where all five compounds are available and a different colouring system is used. C2, C3, and C4 are coloured the same as the hard, medium and soft tyres respectively, and C1 and C5 have the white and red Pirelli logo respectively with no coloured sidewall.

The History of Tyres in Formula 1. Kevin Young. March 31, 2017.

One of the most significant roles in Formula 1 racing are played by the tyres. Throughout the history of Formula 1, from when it was first introduced in 1950 up until now, racing tyres have undergone a lot of major changes that have impacted the sport from what it was, to what we know and love today.

A majority of the changes to Formula 1 tyres changes were triggered by various technological advancements and the quest by manufactures in the automobile industry to provide a better and safer driving experience for both the driver and spectators of the sport. Tyre manufactures recognised the fact that the tyres are the first point of contact between the track and the car so it needs to be able to withstand any and all obstacles to ensure the safety of the driver.

1950s

Stirling Moss.

The first tyres used in Formula 1 were thin and tall, with treads. All four of the car’s tyres were the same size and manufactured by Pirelli.

1960s

The early 1960s saw the introduction of wider and fatter tyres designed to stabilise the cars when making sharp turns. Towards the end of the 1960s, Dunlop introduced the idea of using different sized tyres on the same car: bigger in front and smaller in the back.

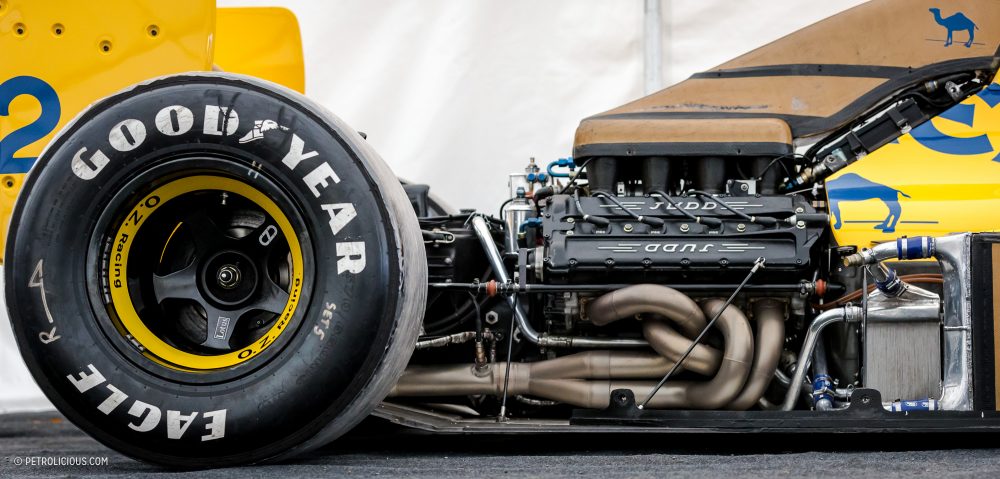

A Lotus. Photo by Petrolicious.

1970s

Slick tyres were first seen during the Formula 1 racing season in 1971 released by Goodyear, the design was introduced to provide more grip in wet weather conditions, something the slick wheels couldn’t accommodate. By 1977, tyre sizes were wider and bigger, the tyre positions were also switched so that the front tyres were smaller while the rear tyres were taller and wider. Around this time Michelin also released the first radial tyres, which were designed to give the driver a more constant ride height in reaction to the aerodynamics.

Vintage Ferraris F1.

1980s

Previously the manufacturing of Formula 1 tyres was handled by specific companies mainly through competitive pricing at tender. But, by the 1980s, the market grew fierce and companies were now competing to win bids by trying to create the best tyres.

A girl on a Ferrari F1.

Companies like Goodyear, Michelin and Pirelli won a majority of the bids and were therefore the sole providers of tyres. Goodyear went on to manufacture Formula 1 tyres from the 1980s up until 1997. This period also saw the reduction of the tyre sizes, and the front and rear tyre sizes started to even out to what we have today. In 1985 we saw tyre blankets being used for the first time. They were used to extend the lifespan of the tyres by warming them up while at pit stops.

1990s

The first major change to Formula 1 tyres in the 1990s was when grooved tyres were introduced, which also marked the end of Goodyear’s tenure as the official Formula 1 tyre providers. Grooved tyres were meant to improve grip and handling around sharp corners. Formula 1 approved tyres were later required to have 3 groves in the front tyres and 4 in the rear tyres.

2000s

From the late ’90s up until 2008, regulations about tyres got tighter.

Mechanics and tyres in the Ferrari pits.

Mechanics and tyres in the Ferrari pits.

Mechanics and tyres in the Ferrari pits.

Mechanics and tyres in the Ferrari pits.

They required a minimum of four grooves in order to slow down the cars. They also specified the sizes of tyres depending on weather conditions. For the period 2005 to 2006, tyre changes were disallowed during races, which made it harder for vehicles to complete a whole race, as the tyres were not designed for such distance. This regulation was later over-turned in 2006 after some controversy surrounding the 2005 US Grand Prix. In 2009, slick tyres were also reintroduced at the start of the season along with other changes that stabilise the mechanical grip, especially when overtaking. From 2011 up until now Pirelli continues to be the sole provider of tyres for Formula 1 racing.

The pneumatic tyre was invented by John Boyd Dunlop, a veterinary surgeon, in 1888. It was intended for his son's tricycle, to make travelling over the cobblestones both faster and smoother. The year after it was patented, this tyre was fitted to a bicycle and won it's first race. These early tyres consisted of a rubber tube filled with air, enclosed by rubbered canvas, which was wrapped around the wooden rim. The method of attaching this tyre to the rim was gradually improved until it reached it's current design around 1920. Being leaders in their field, it was not long before Dunlop tyres were sought after for racing. They were Dunlop tyres that won the very first Le Mans 24 hour race, in 1923.

But these early race tyres were merely standard tyres. Tyre design then was barely keeping up with the demands of improved vehicle developments. At this stage Dunlop began developing specialised tyres for competition, firstly with the 5 Stud pattern in 1934, and then in 1946 the R1. By today's standards these tyres were very crude, being made of cotton fabric and genuine tree rubber; they weighed about 38 lbs. They were very popular however, remaining competitive until the R3 was introduced in 1955. The R4 followed soon after in 1956 as a wet weather version.

The next breakthrough came in 1958 when Dunlop introduced the use of nylon fabric with the R5, reducing weights by 12 lbs. per tyre. It was in this pattern that Dunlop introduced the first synthetic tread compound, now known as 'green spot' by its colour coded identification. In the late fifties the American giants, Goodyear and Firestone entered the European scene, however Dunlop continued to dominated Formula 1. The R6 was introduced in 1962, incorporating improved nylon casings and reduced aspect ratio. Major developments followed soon after, including the use of synthetic rubber for tread compounds and lower aspect profiles. The R6 pattern was also called the CR48 and was followed by the R7 (CR65) in 1965.

The first slick type tyre was produced by Dunlop in 1966 called the CR70. However this was ahead of its time and proved unsuitable for the compounds available then. As we now know, a tyre needs a certain amount of 'flexibility' in the tread to give it 'progression'. Without this it feels like steering a truck tyre. Earlier tyres achieved this 'progression' by the inherent flexibility of the tread pattern. Current slick tyres achieve this effect by the use of soft tread compounds. However the compounds used then were far too hard for this pattern. The next pattern development was the CR82 in 1968, a much more traditional style, which was a development of the earlier CR65. In the late '60s other developments rapidly followed, largely as the 'tyre race' developed with Goodyear and Firestone. These included extended use of depressed contour moulding, aspect ratios as low as 40, and tubeless construction.

The CR84 was introduced late in 1968, winning Jackie Stewart his first Formula One world championship in 1969.

Dunlop officially withdrew from F1 at the end of 1969 with their last patterned tyre, the CR84, citing lack of relevance to road tyre development. Interestingly, the adoption of 'slick' type treads followed immediately. At that time road tyres were rapidly changing to radial construction, then totally unsuited to the demands of racing.

Two years later, Stuckey tyre service became involved with Dunlop race tyres in Australia, first as distributor for Victoria, South Australia, and Tasmania and later for the whole of Australia. In that first year of 1972, Australia saw slick tyres for the first time. Their use quickly spread to all categories. Australia's most important race, Bathurst, was won on slicks for the first time in 1972, by Peter Brock in a Torana. These were Dunlop slicks. Co-incidentally hand grooving was also introduced in that race as wet weather was experienced. It was Harry Firth, then manager of the Holden Dealer Team, who pioneered this development in conjunction with Dunlop Racing Service in Australia.

MODERN DEVELOPMENTS OVER THE PAST 20 YEARS: RADIAL CONSTRUCTION

This construction was pioneered for racing by Pirelli and Michelin but first examples were uncompetitive with bias ply construction.

Michelin first produced radial slicks in 1972. Their first use in F1 was with Jody Scheckter and Ferrari in 1979. This was the first time that radial tyres had been used in f1. Michelin pulled out from F1 at the end of 1984, probably partly due to the very high cost of involvement. In those 6 years they had won over 50% of races. This forced Goodyear into producing radial tyres also. Pirelli were the first to introduce radial slicks into F2 in Europe around 1978. Several years later they also entered F1 with radials.

Radial tyres have an inherent advantage of improved traction & braking, and improved compound durability compared to bias ply tyres. This is due to the reinforcing belt under the tread, which promotes a stable, evenly loaded contact area. However this also was directly responsible for making the tyres very difficult to control at the limit of grip. Sudden 'breakaway' was a very serious problem, similar to that problem experienced with the early Dunlop CR70. Developments with radial tyres then were in the areas of making them more 'driveable'. This attribute has not been a factor in developing passenger radials for street use as it is not envisaged that tyres will be driven continually at the limit of adhesion.

Bias ply tyres have an inherent advantage for racing due to their ease of car control at the limit of adhesion. This makes them the most popular tyre for most classes of racing. However increasing limitations in tyre widths is showing the benefits of radial's durability to the extent that this construction is gradually being universally adopted.

There is now a rapid reduction in the availability of bias ply tyres.

TUBELESS CONSTRUCTION

All modern tyres are of tubeless construction, whether for race cars, road cars, trucks or aeroplanes. Most rally tyres are also tubeless. The technical benefit is in the reduction of mass, a major obstacle to tyre performance. In practice tubeless construction also makes the tyre much more user friendly, as punctures are much less catastrophic.

COMPOUND TECHNOLOGY

As explained earlier, the original tyres were made with pure natural rubber, vulcanised and (later) compounded with carbon black for durability. Modern tyres are comprised mainly of synthetic rubber. Early commercial advantages of synthetic rubber were the stable and reliable costs compared to natural rubber, which was farmed in Asia and Africa. However modern polymers can be formulated to produce exactly the right properties required for different parts of the tyre's construction; bead, sidewall, tread etc. This is obviously crucial in the tread compound of slick tyres, but equally important for all other types of tyres. The major beneficial property of modern race tread compounds is 'hysteresis'. This is the rubber's ability to absorb mechanical energy and transform it into heat energy, which in turn lowers the rubber hardness, similar to warming up a squash ball. A highly efficient rubber ball when bounced, returns nearly all its energy by rebounding to almost the same height. This rubber displays low hysteresis. A high hysteresis rubber ball such as a squash ball will rebound to a much lower height, converting some of it's kinetic energy into heat energy. This is exactly why modern slick compounds get 'hot & sticky'.

ASPECT RATIOS

These have changed drastically, illustrating an example of road tyres following racing trends. The earliest tyres had an aspect ratio of about 100%, that is the tyre section was roughly circular, having similar section width and section height. This has reduced to about 30% for some racing (and road) applications. Surprisingly some modern racing tyres have climbed back up to about 50%, even in Formula 1!

TYRE MATERIALS

The need for low weight and strength has promoted new materials for race tyres. These include kevlar (aramid) and fibreglass, as well as other more secret exotic fibres. The current touring car race tyres as used at Bathurst use nylon casing, steel belts, nylon overlay and kevlar for sidewall strengthening. Surprisingly kevlar has readily found several applications on road tyres despite its high cost. The latest high performance road tyre from Dunlop Japan, the Formula FM-901, incorporates a blend of nylon and kevlar in the belt overlay.

Dunlop Motorsport continues to make a very wide range of historic tyres.

Every Formula One car’s performance is highly dependent on the type and compound of F1 tyres put to use. The modern F1 cars could be a technical masterpiece but without the proper compound of tyres, even the very best car cannot stand a chance.

The development of the F1 racing tyre came of age with the appearance of 'slick' un-treaded tyres in the late 1960s and early 1970s. Teams and tyre makers realized that by omitting a tread pattern on dry weather tyres, the surface area of rubber in contact with the road could be maximized. Until 1998 season Formula 1 cars ran with slicks, then ‘grooved’ tyres were introduced to curb the cornering speeds. Those grooved tyres had three grooves in the front tyres and four grooves in the rear tyres.

The regulations specified that all tyres had to have four continuous longitudinal grooves at least 2.5mm deep and spaced 50mm apart. These changes created several new challenges for the tyre manufacturers - most notably ensuring the grooves' integrity, which in turn limited the softness of rubber compounds that could be used.

For 2007, Bridgestone became the sole tyre supplier in Formula One, they introduced four compounds of the tyre, two of which are made available at each race. The harder tyre (Prime tyre) is more durable but gives less grip, and the softer tyre (Option tyre) gives more grip but is less durable.

From 1950 to 1960 the F1 tyres were manufactured by 5-6 companies, Pirelli, Firestone, Dunlop, Englebert, Avon, and Continental. Then for the following three years, Dunlop was the sole tyre manufacturers for Formula One racing. Then for almost two decades till the 1980s the tyre compounds were provided by Dunlop, Goodyear, and Firestone.

A girl on a tyre. From the Pirelli calendar.

Until Pirelli came back to F1 market shared space along with Goodyear then became the sole tyre suppliers from 2011 till date replacing Bridgestone and Michelin of 1990s.

Current F1 tyre suppliers Pirelli has a range of seven dry-weather F1 tyre compounds for 2018 Formula One Season.

Despite the development effort invested in aerodynamics, composite construction and engines it is not easy to forget that the nitrogen mixture filled tyres are still an F1 car’s biggest single performance variable and the only point of contact between car and track.

Videos

Comments

Authorize to comment