He wanted to hear the noise of the Red directly in his own home. He built a Ferrari working scale model from scratch, all by himself, in his garage. This sentence, difficult to grasp in the entirety of its scope, makes us understand the stature of the man and the level of his passion. A mission bordering on the impossible, accomplished after years of ferocious application and unshakable trust in his means. Watching his hands approaching his model with infinite softness allows you to understand the love and sense of protection for his creature.

The smallest Ferrari in the world. "The car can run, we just need to find someone to drive it" says Scerri in reference to someone who will have to be no more than 50cm tall.

A fifteen year quest to build a perfect miniature Ferrari race car. Pierre Scerri is a French telecommunications engineer and model builder, who gained fame in 1998 after having his highly accurate 1:3 scale model of a Ferrari 312 PB featured on the BBC programme Jeremy Clarkson's Extreme Machines.

The Ferrari 312 PB was originally introduced by the Italian high-end carmaker in 1971 as part of the Ferrari P series of Prototype-Sports Cars, but was re-designated as a Group 5 Sports Car for 1972, winning all of the World Sportscar Championship races it entered that season.

Scerri, back in the 1970's a big racing fan, was smitten and set himself the task of creating a 100 percent accurate scaled-down replica. “When I was younger, I saw Ferrari in many races, and my dream was to get this Ferrari sound – this music – at home,” says Scerri of the inimitable Ferrari engine noise. "I didn’t have the money to buy one so I had to make one. I wanted to make something like a dream – a Ferrari which I could have in the dining room. That was the challenge I set myself and to achieve it I had to learn how to make everything in this car."

He began his project for the model in 1978. Pierre Bardinon, owner of the Mas du Clos race track, allowed Scerri to take detailed photographs of the actual car on display at the adjacent Ferrari. Scerri not only made every single part himself, but also had to make and design the mould for every single part. “I took photos of the real car and made all my own drawings from these photos. That phase took three years. Then to build the actual car took me another 12 years.”

The 12-year construction odyssey took Pierre on a journey though virtually every process needed to build the full size car. He learned to mold his own rubber tires, cast his own glass headlights, make his own battery, weld the tube frame, build the shock absorbers and such delicate tasks as making a miniature tachometer and other working gauges. The drawing and machining skills were learned from reading books, as he had not been given any training in these subjects when in school.

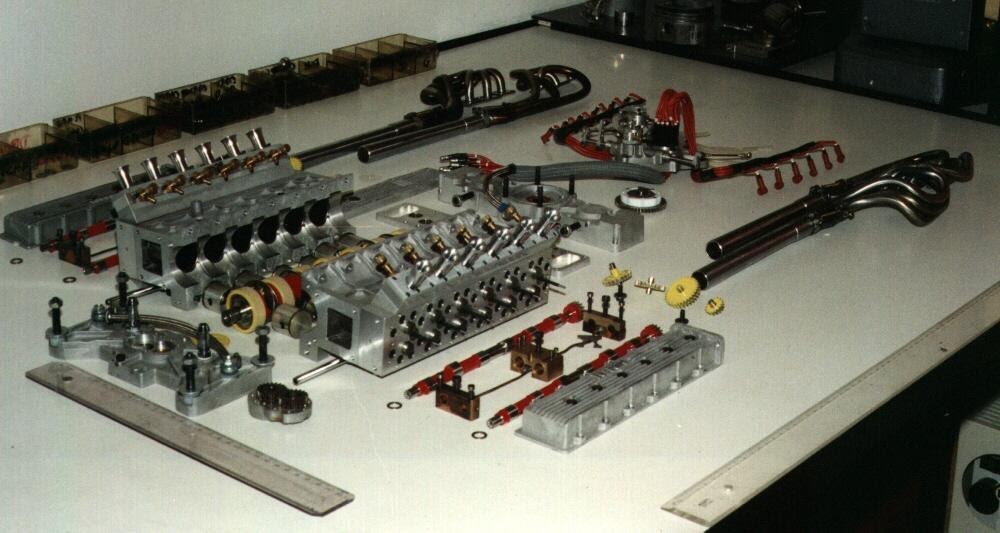

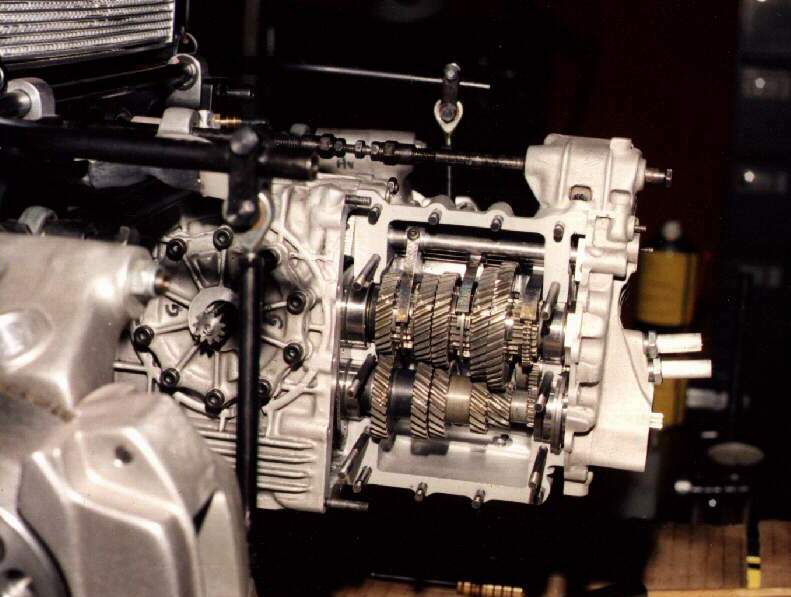

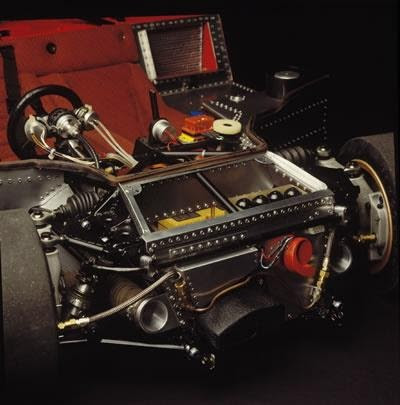

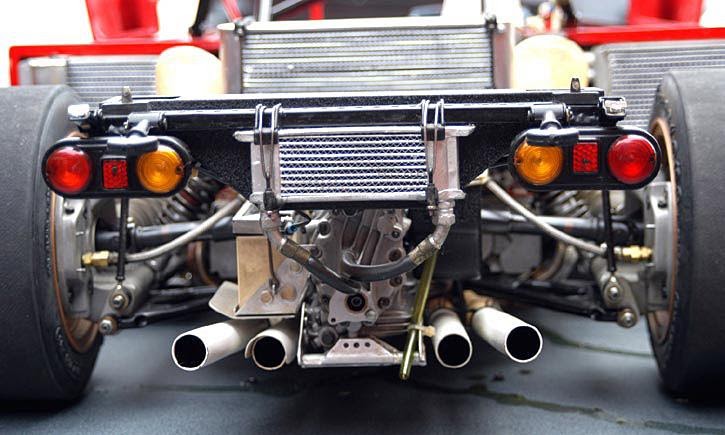

Of course, there was the running 100 cc, fuel injected, dry sump, four-stroke internal combustion, flat 12-cylinder engine, with 24 pistons; the heart of the car that had to be built too. The engine alone took three years, and just tuning the exhaust to get the proper "Ferrari music" took almost six months (and three different sets of exhaust pipes) before Pierre was satisfied. “I made the engine all by myself because I wanted to get the right sound,” he says. “I needed a 12-cylinder, fuel-injected engine with a dry-sump. So I made everything myself down to the valves and the valve springs.” To learn pattern and mold making to do the castings, he attended a foundry school in Marseille. Bodywork, upholstery, electrical system—all had to be fabricated from scratch. The only part that required some collaboration because of its exotic metallurgy and tight machining specifications was the gearbox. For this Pierre was able to work with Colleti, the famous builder of the full-size Ferrari racing gearboxes who lent their expertise in making the actual gears used inside the cast case. The 5-speed box also has a working reverse gear. In 1989, he finally completed assembly of the engine, a scaled down version of the original one that purrs like only a Ferrari can purr.

In total, Pierre estimates a total of over 20,000 hours was devoted to completing the car, which was finished in 1992.

In building the car, Scerri tried to remain as true to the original as possible. When upholstering the interior, he went to the person who had originally done the interior for the real race car and asked if he could supply a piece of material as close to the original as possible. They went through their leftover supplies and found an actual piece of the original material used in the full-size car, which is what Pierre used in the model. Naturally, the pattern in the material is not scaled down to 1/3, but Pierre felt it was worth the compromise to have the opportunity to use the actual material from the real car.

The fuel system is pressurized just like the real car. When fueling the car to run it, fuel is pumped with an electric pump into the filler cap near the driver's right side. An overflow bottle is inserted into a fitting on the cap on the left side. When the tank is full, fuel overflows into the catch bottle on the left side. The pump is then shut off, the fuel filler line removed and then the catch bottle removed, just as a pit crew would do it on the real car.

The fuel used when running this car is methanol with 5% nitromethane mixed in. The original spark plugs he made were replaced with glow plugs as a practical consideration in running the car for demonstrations, as the spark plugs were functional but not very reliable. A little special oil is mixed with the fuel to keep the fuel lines and other components from deteriorating due to the corrosive nature of the fuel. This is why you will see some smoke when the car is run. Pierre also says that after being run many times since being completed in 1992, the engine has never been rebuilt and the rings could probably use replacing. A second car is now under construction that will wear the number 30. The original #30 car won at Buenos Aires in 1972 with Peterson and Schenken behind the wheel. This model will run on gasoline and be fired by 24 actual spark plugs (2 per cylinder). It will also have a built in electric starter that will work with the turn of the key rather than the external starter used on the #3 car.

Pierre calls this car "a dream—a car you can park in your dining room."

When it was completed, the engine fired on the first try. Since then it has been run a total of over 50 hours at the many shows and demonstrations Pierre attends with the car. There has not been one failed part in all that time. This is a record of reliability that the real race car would probably envy. It all works too—ignition key, lights, clutch, gearbox, suspension, radiator, brakes and so on.

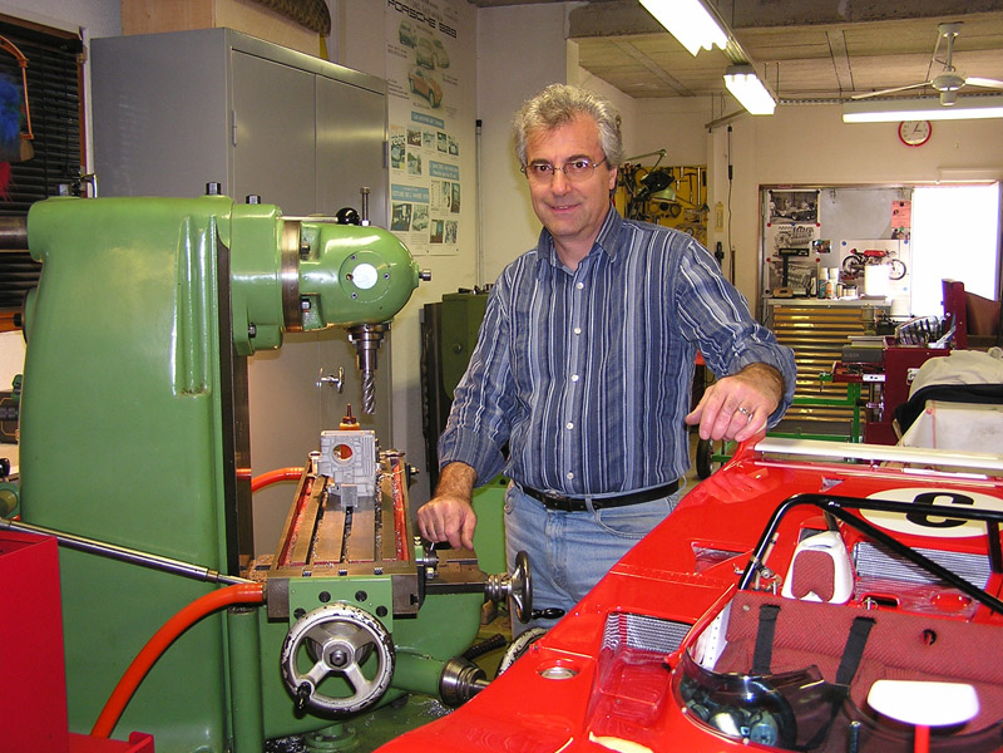

Pierre is seen with some of the machine tools in his compact but well-equipped shop.

Scerri is now working on 3 new models, a Ferrari 330 P4, another Ferrari 312PB and an engine for a Ferrari 250 GTO, all 1:3 scale. Fifteen years, however, is just too long to take for each future car. At this time, the car spends part of the year in Avignon, France with Pierre and part of the year in the United States residing with Fine Art Models in a Detroit suburb in Michigan. To finance this operation, Pierre is now building a larger shop that does restoration on full size vintage race cars and plans to bring on more staff to help with production of future projects to both speed up the process and make it a profitable business. In making every part of the small Ferrari, he has become an expert in the processes needed to build all the parts of a race car from scratch. In addition to working on full-size cars, Pierre will be able to continue with his love of the miniature cars as well. It is still amazing to see the level of craftsmanship he put into his work.

Pierre and the Ferrari appear in person at the North American Model Engineering Society Expo in Toledo in April, 2007

Joe Martin presents Pierre Scerri with the award plaque and medal as winner of the Foundation's 2007 "Metalworking Craftsman of the Year" award at the 2007 NAMES show in Toledo, Ohio.

Model engineers in the United States had a rare chance to view the car and to meet Scerri in person at the 2007 North American Model Engineering Exposition in Toledo, Ohio. Pierre was there to accept his award as "Metalworking Craftsman of the Year" for 2007 and fired up the car at least three times a day on Friday, Saturday and Sunday.

In 1996 Pietro Meloni decided to participate, by exhibiting small Roland numerical control milling machines, at the modeling exhibition in Novegro, Italy. He said about it: “the model makers attracted me: true fans of mechanics, creatives, lovers of experimentation of techniques and materials. While setting up the small stand, I occasionally peeked at the nearby stands, where extraordinary "toys for grown-ups" slowly found their place: ships, cars, tanks, submarines, engines, trains made with the finest details. I'm in the right place, I thought. I had almost finished arranging my space and every now and then my eye fell on the stand next to mine, the only one totally empty. Maybe they won't have rented it, I said to myself. Too bad, I would have taken it. I finish sticking the stickers, check that everything works and close up the stand, regretful for the missed opportunity. The next day, just before the opening to the public, a gentleman arrives, pushing a trolley with a large sports car model. He goes straight to the empty stand. He puts it in the center and covers it with a cloth. I dedicate myself to other things, forgetting about my neighbor. I turn on the machines, prepare the computers, ready to receive the public. And the public arrives. And what an audience! At the opening of the exhibition, a large group of evidently important people enter from the back of the hall, surrounded by cameramen, photographers, journalists. They come straight to me. Maybe it will be a TV crew, I think. Sometimes at exhibitions it happens ... I hope they will film my stand too ... And it would seem so ... But at the last moment, the platoon stands in front of my silent neighbor's stand. He removes the cloth from the car, puts the keys in the dashboard, and starts the engine. The roar is unmistakable: Ferrari, 12 cylinders. The several hundred people in the stand are dumbfounded. The man gives some abrupt acceleration to the engine, runs it for a few minutes and switches it off. The silence of the room still lasts several minutes.

Well, needless to say, I spent the three days of the exhibition exclusively talking to him, letting me tell his story and that of his wonder. Pierre Scerri, French, was a telecommunications engineer. Never made modeling in his life. In 1978, on his honeymoon with his wife (on a motorbike), he witnesses a prototype race. He sees a Ferrari 312PB, falls in love with it and decides to build one to keep in the living room. But he wants it to be real. He is obsessed with this project. He writes Ferrari to ask for the drawings (of course, without receiving an answer). So he decides to visit Pierre Bardinon, owner of the Mas Du Clos race track and collector who owns one of the three specimen of the car. Pierre must have been convincing because he gets permission to photograph and even dismantle the car. He gets to work. The realism is impressive. Pierre builds every detail. The car must function like the real one, in all respects.

So, he learns to blow glass to make 1: 3 scale double-filament bulbs. He makes real tires, learning how to vulcanize rubber. He learns to weld titanium as the original chassis is titanium made and the same must be the one of the model. He even builds a special sewing machine with 1: 3 scale stitches for sewing the upholstery.

He produces the 1: 3 scale rivets, the battery, the seven radiators with which the car is equipped, the candles ... everything. The level of perfectionism can only be understood by thinking that - to obtain the same engine noise - he records the sound of the real one, analyzes the waveform and takes about 3 years to set it up. Coming to define a special mapping of the electronic control unit because, for reasons related to the impossibility of scaling the air-fuel ratios, the engine of the model starts immediately while in the real car some cylinders initially have difficulty starting.

Pierre Scerri at the “helm” of his manual milling machine.

Pierre Scerri's life changes. He gets a lifetime consultancy contract from Ferrari. He is invited to various Ferrari clubs around the world to show his wonder. He gets rich, producing and selling (for figures surpassing the original) six exclusive replicas of his model. However, remaining a simple, humble man, more comfortable in the workshop than at a press conference. Ah ... I forgot ... all made with manual machines ... Without CNC”.

Videos

Comments

Authorize to comment